3D printing ink gel is revolutionizing various industries by enabling the creation of complex, customized

structures with precision and efficiency. This innovative material is composed of specialized polymers

and additives that allow it to be extruded layer by layer to form solid objects. Just as cancer involves the

uncontrolled growth of cells, 3D printing ink gels must be carefully formulated to maintain control over

the shape, strength, and stability of the printed structures. The gel’s unique properties, such as its viscosity

and ability to harden quickly, make it ideal for applications in fields like healthcare, aerospace, and

construction. The continuous development of these ink gels is critical, as they allow for the production of

more complex and durable objects, ultimately reducing costs and enabling faster prototyping.

The development of advanced 3D printing ink gels offers numerous advantages in fabricating highly

customized and functional structures for diverse applications. To fully harness the potential of 3D

printing, intelligent ink formulations must be designed to improve the precision, strength, and versatility

of the printed objects. This is crucial for creating structures that meet the specific requirements of fields

like biomedicine, aerospace, and construction. Although various ink gels exist, many challenges remain in

translating these materials into fully functional devices or components due to limitations such as

inadequate mechanical properties, high production costs, and poor scalability. Addressing these issues

requires the development of ink gels with enhanced payload capacity, better tunable properties, and

greater ease of manufacturing, ensuring more efficient and cost-effective production keeping the exacting

demands of each application.

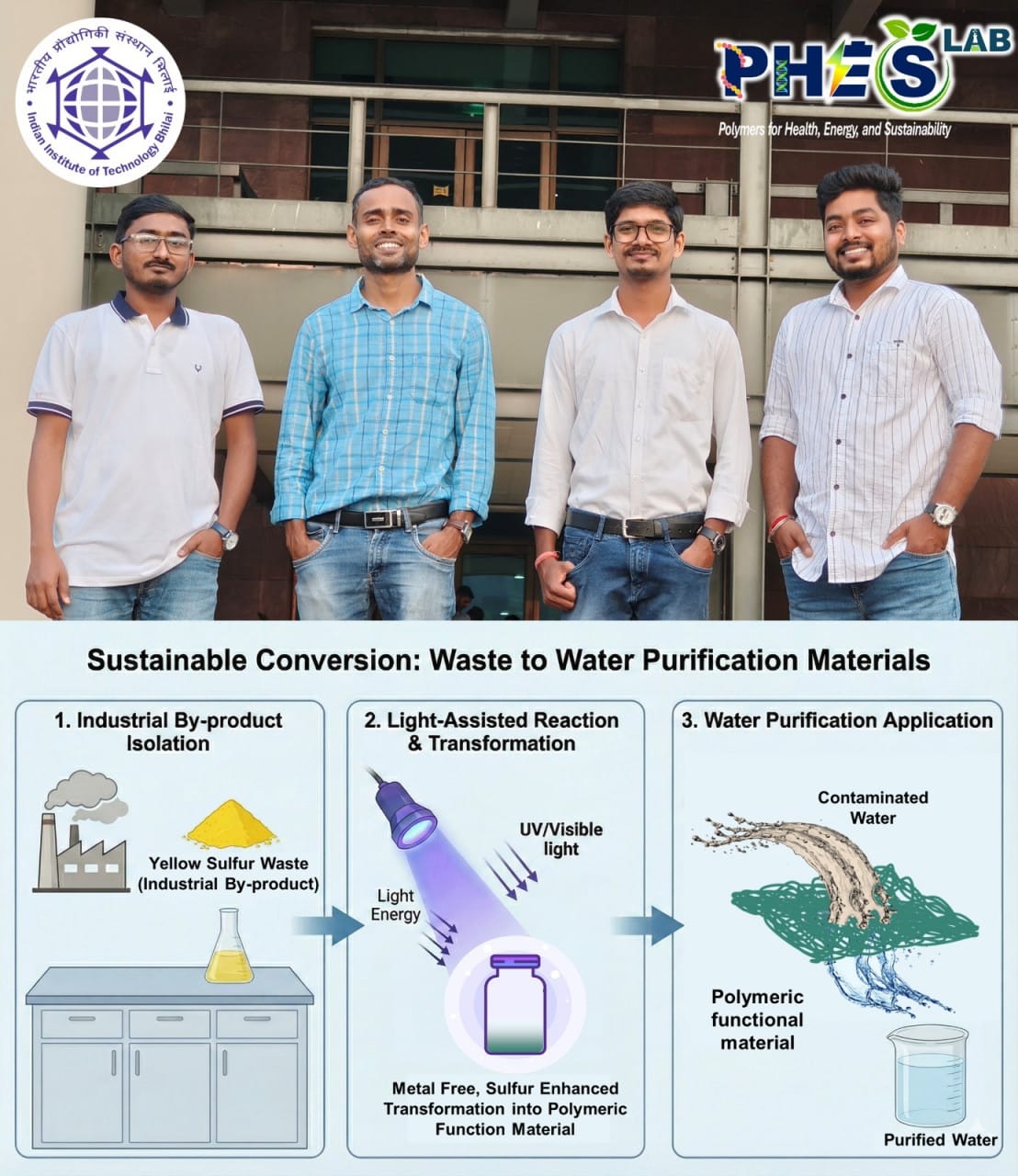

Researchers at IIT Bhilai, led by Dr. Sanjib Banerjee from the Department of Chemistry, have developed

a “smart injectable ink material for 3D printing”. The material is developed via a simple and cost-

effective “industry-friendly” process and enables production of cost-effective 3D printing ink. This work

has been published in Advanced Functional Materials, an internationally reputed journal. The research is

supported by the IIT Bhilai, DSIR, Govt. of India and SERB, Govt. of India. The article can be accessed

through the following link:

https://doi.org/10.1002/adfm.202415125