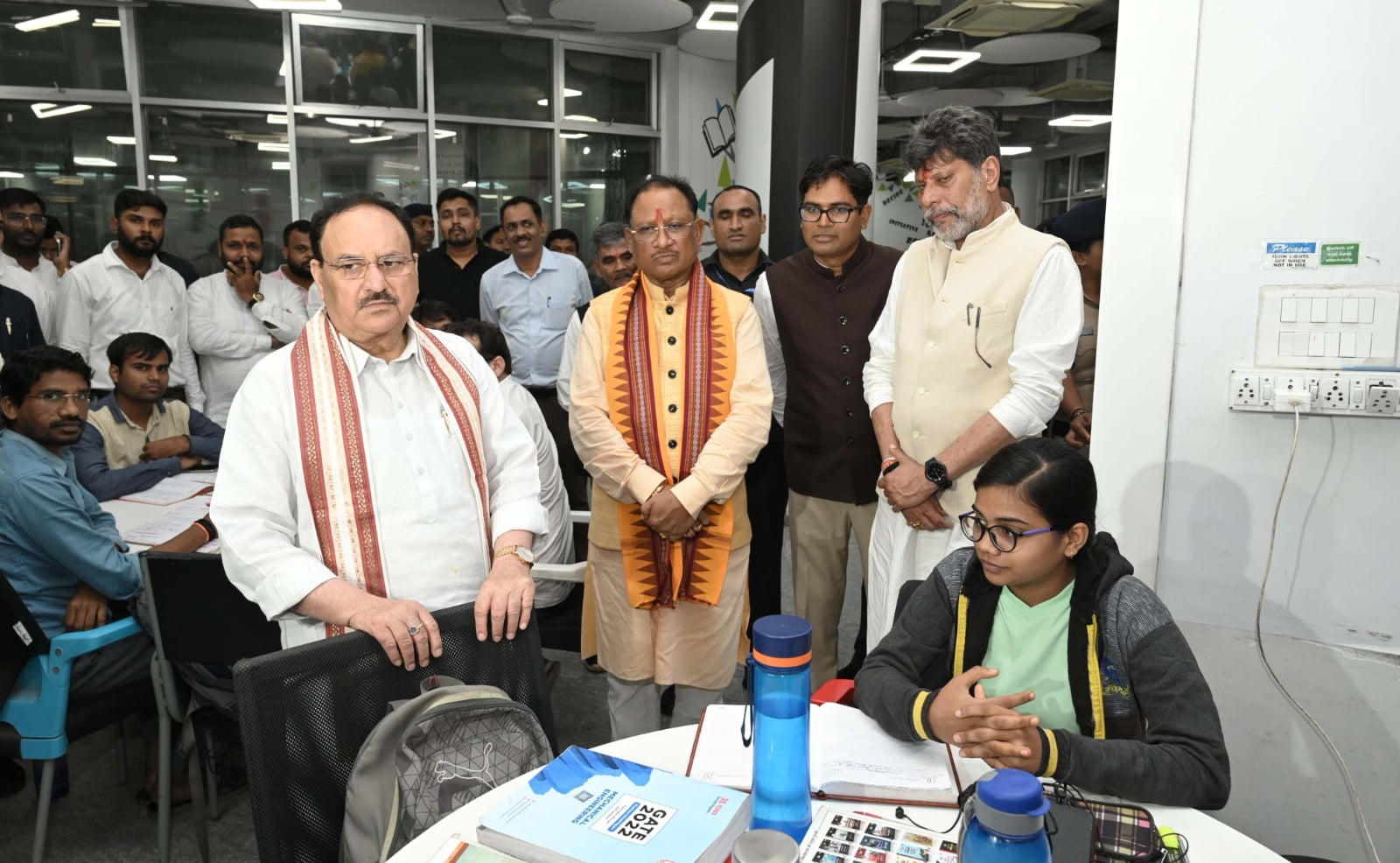

MATS University Raipur, School of Sciences organized an industrial visit to Sarda Energy and Mineral Limited Siltara on 15 May, Thursday for the M. Sc. Chemistry and B. Sc. final year students of the university. The visit was conducted with the prior permission of Vice Chancellor Prof. (Dr.) K.P. Yadav and under the guidance of Professor & Head, School of Sciences Dr. Ashish Saraf. Sarda Energy and Mineral Limited (SEML) is recognized as one of the lowest cost producers of steel (Sponge Iron, Billets, Ferro Alloys, Mining, Power, Pellets, Iron Ore, Wire Rod Mill, Eco Bricks) and stands as one of the largest manufacturers and exporters of ferro alloys in India.

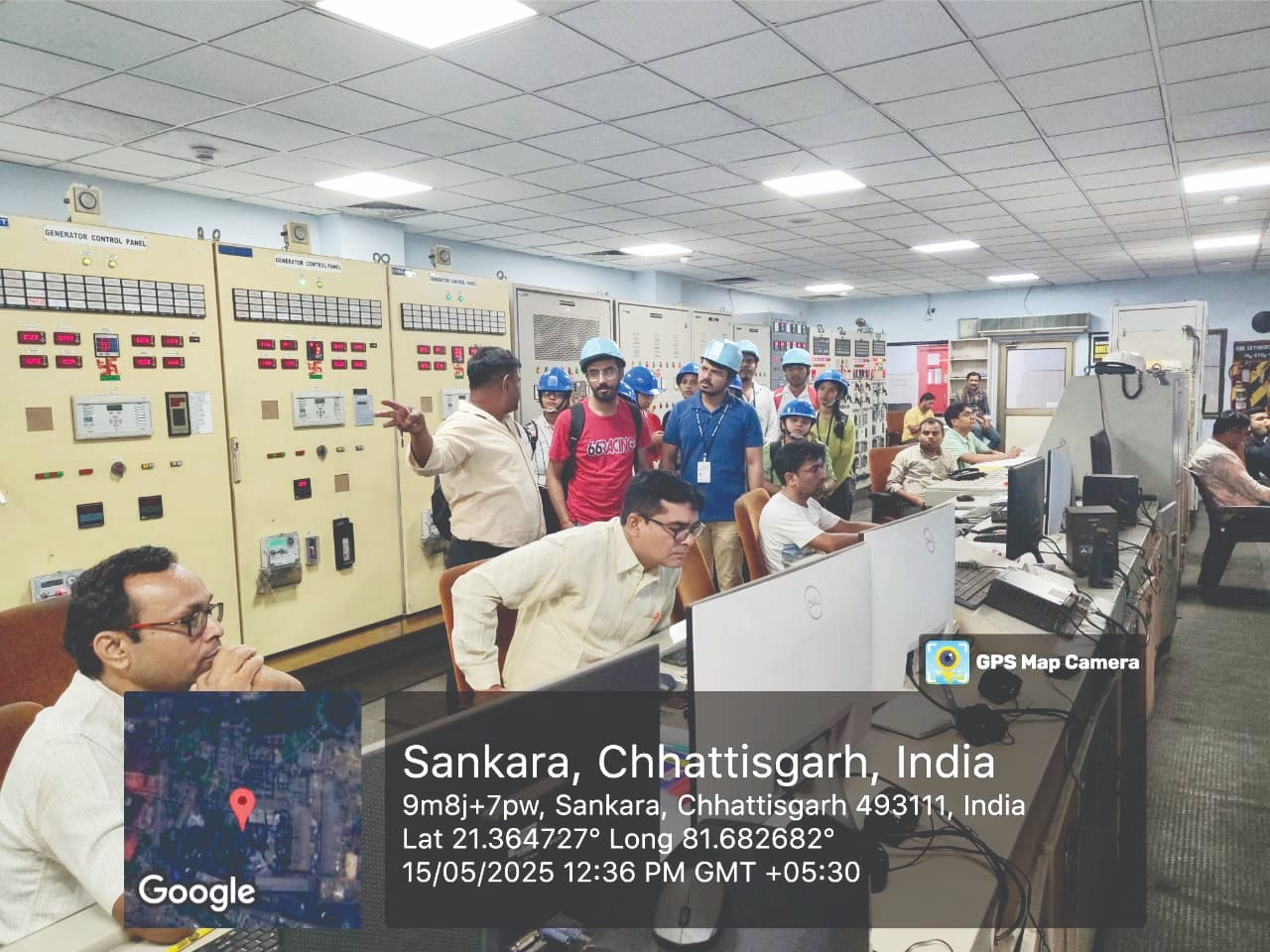

The objectives of this industrial visit were to learn about the functioning of a coal-based steam power plant, understand the coal to electricity cycle, and explore the best sustainable practices in operating a coal-based power plant. Additionally, this visit aimed to provide students with practical insights into the operations of a steel industry, enhance their understanding of industry practices, and explore real-world applications of their academic learning. Under the direction of AGM-HR Surendra Kumar Lanjewar, the training team, including Manager (CAG) Parmanand Sen, OP Agrawal, and Rakesh Verma from the HR team, led the visit. The industrial visit at Sarda Industries commenced with a briefing on security protocols to be followed during the plant tour and the distribution of helmets to students.

Quoting ‘Synergy is energy’, a documentary presentation on the company’s production at both national and global levels was delivered by the Technical and HR team. The presentation also emphasized the quality management system, health safety, and environmental sustainability.

The students were educated about various thermal power plant equipment, including the coal handling plant, ash handling plant, boiler, super heater, air pre-heater, economizer, turbine, chimney, feed pump, generator, switch yard, and transformer.

Subsequently, the students visited the sponge iron division, where they observed the process of converting iron ore into sponge iron, a crucial intermediate in steel production. Expert engineers addressed the students, highlighting the plant’s layout, equipment, and safety protocols, with a particular focus on the DRI process, which involves reducing iron ore with a reducing gas or elemental carbon to eliminate oxygen and produce metallic iron.

The industrial visit was well coordinated by faculty from School of Sciences Professor Dr. Nitin Jaiswal, Dr. Avidha Shrivastav and Dr. Siddharth Kumar.

The visit proved to be highly beneficial for the students, providing them with insights into the industrial processes and practical understanding of power production. It also fostered a deeper appreciation among the students for the hard work and dedication of employees working in such challenging environments, supporting the demands of modern industries. Furthermore, it underscored how a company can maintain stability through innovation and resilience, offering students a practical glimpse into how theoretical concepts and leadership are applied in a dynamic industrial environment.